Overview of Color Fastness to Washing test Standards

Color fastness to washing test is a critical parameter in textile quality assurance. It measures a fabric’s resistance to fading or bleeding its color during domestic or commercial laundering. For global brands, textile manufacturers, and testing laboratories, adhering to internationally recognized standards is not just about quality—it’s a prerequisite for market access and consumer satisfaction. Different regions have developed their own rigorous test protocols, primarily ISO 105-C06 (European/International), AATCC 61 (American), and JIS L 0844 (Japanese). Understanding their similarities and differences is essential for anyone in the global textile industry.

II. What Is Color Fastness to Washing?

Color fastness to washing is defined as the resistance of a textile’s color to various forms of degradation and transfer when subjected to washing processes. Its significance lies in ensuring that a garment or fabric maintains its intended appearance throughout its lifecycle, preventing color loss (fading) and the staining of other garments in the same wash (bleeding).

It is distinct from other fastness types like:

- Color Fastness to Light: Resistance to fading from sunlight or artificial light.

- Color Fastness to Rubbing (Crocking): Resistance to color transfer due to dry or wet friction.

- Color Fastness to Perspiration: Resistance to color change or staining from acidic or alkaline perspiration.

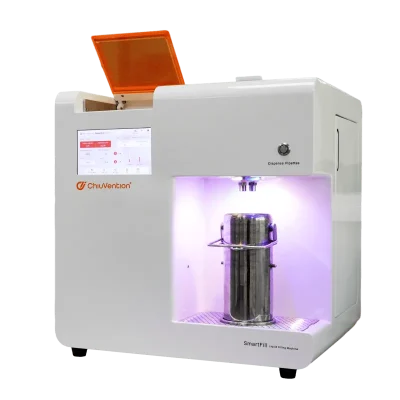

In the lab, a washing fastness tester (or launderometer) is used to simulate accelerated washing conditions. It consists of a heated water bath that rotates multiple sealed stainless-steel containers (cans), each holding the test specimen and the specified washing solution under controlled conditions of time, temperature, and mechanical action.

III. Common Color Fastness to Washing Test Methods

While regional standards differ, the core principle remains the same: to simulate multiple domestic washes in a single, accelerated laboratory procedure. A specimen of the textile is washed under specified conditions while in contact with specified adjacent fabrics (e.g., multifiber or single-fiber fabrics) to assess staining.

After the test, two aspects are evaluated separately using standard gray scales:

- Color Change (Gray Scale for Color Change): Assesses how much the original test specimen has faded or changed in color.

- Staining (Gray Scale for Staining): Assesses how much color has transferred from the test specimen to the adjacent fabrics.

Ratings are on a scale of 1 to 5, where 5 represents excellent fastness (no change/no staining) and 1 represents very poor fastness.

IV. ISO 105-C06: The European/International Standard

ISO 105-C06, “Colour fastness to domestic and commercial laundering,” is the most widely used standard internationally, especially in Europe and many other regions outside North America.

- Test Conditions: The standard offers multiple test severity levels (e.g., C06-A1S, C06-B2S, C06-C3S, etc.), which vary by temperature (40°C to 95°C), number of steel balls added to increase mechanical action, washing time, and detergent composition. The specific test condition is chosen based on the expected real-life washing environment for the textile.

- Typical Applications: It is the benchmark for EU compliance and is heavily specified in international trade. Its modular approach allows for precise testing tailored to the product’s end-use.

V. AATCC 61: The American Standard

AATCC 61, “Colorfastness to Laundering: Accelerated,” is the predominant standard in the United States. It is explicitly designed to simulate multiple home launderings in a single, short test.

- Explanation: The standard defines several test conditions (1A through 3A). For example, Test 2A is designed to simulate five typical home launderings. It uses a precise detergent without optical brighteners and specifies a much lower liquor ratio (the ratio of solution volume to fabric weight) than ISO, creating a more abrasive environment.

- Reporting: Results are reported as a color change grade and a staining grade, similar to ISO.

- Key Differences from ISO: The most notable differences are the use of a specific AATCC detergent, a lower liquor ratio, and a different can size and rotation speed in the washing fastness tester. These factors often make AATCC 61 a more severe test for staining compared to an ISO test at a similar temperature.

VI. JIS L 0844: The Japanese Standard

JIS L 0844, “Testing methods for colour fastness to washing,” is the Japanese industrial standard. It is widely used in Japan and influences testing requirements in other Asian markets.

- Test Procedure Overview: Like the others, it has multiple test methods (A through D), varying in temperature and severity. A key characteristic is the option to use either a neutral soap solution or a specified synthetic detergent. The mechanical action is also distinct, often resulting in a test severity that can sit between typical ISO and AATCC conditions.

- Applications: Compliance with JIS L 0844 is crucial for products entering the Japanese market, as Japanese brands and retailers often require it.

VII. Comparative Analysis of the Three Standards

| Parameter | ISO 105-C06 | AATCC 61 | JIS L 0844 |

|---|---|---|---|

| Region | International / EU | United States | Japan |

| Test Severity | Multiple tests (A1S, B2S, C3S, etc.) | Multiple tests (1A, 2A, 3A, etc.) | Multiple tests (A, B, C, D) |

| Temperature Range | 40°C – 95°C | 40°C – 71°C | 40°C – 95°C |

| Detergent | ISO Reference Detergent or ECE | AATCC Standard Detergent | Neutral Soap or Synthetic Detergent |

| Liquor Ratio | 50:1 | 20:1 | 30:1 |

| Mechanical Action | Steel balls (0 to 100) | 50 steel balls (for Test 2A) | 10 steel balls (for Method A) |

| Duration | 30 or 45 minutes | 45 minutes (for Test 2A) | 30 minutes |

Why results differ: The same fabric can yield different results under these standards due to the variations in detergent chemistry, liquor ratio (a lower ratio is harsher), and the type/amount of mechanical action. A fabric that passes an ISO test might fail a similarly tempered AATCC test due to the more abrasive low-liquor ratio environment.

Market-driven considerations: The choice of standard is dictated by the target market. Exporting to the EU requires ISO testing, to the U.S. requires AATCC, and to Japan requires JIS. Global brands often require testing against all relevant standards for their supply chain.

VIII. Choosing the Right Washing Fastness Tester

Selecting the correct equipment is vital for compliant and accurate testing.

- Features: Modern washing fastness testers are designed to be versatile. Look for models that can be easily configured to meet the specific can rotation speed, temperature stability, and timer requirements of all three standards (ISO, AATCC, and JIS).

- Compliance: Ensure the equipment is certified to meet the mechanical and performance specifications outlined in each test method standard.

- Selection Factors: Consider cost (initial investment vs. long-term versatility), accuracy (temperature control uniformity, rotation speed consistency), and efficiency (number of test cans, ease of use, and maintenance requirements). A machine that can handle multiple standards is more cost-effective for labs serving international clients.

IX. Conclusion

While *ISO 105-C06, **AATCC 61, and *JIS L 0844 all serve the same fundamental purpose—assessing color fastness to washing—their test conditions differ significantly in terms of detergent, liquor ratio, and mechanical action. These differences mean that results are not directly comparable, and a pass in one standard does not guarantee a pass in another.

For textile manufacturers and brands operating globally, the importance of selecting the correct standard based on the target market cannot be overstated. To ensure broad market access and meet the stringent requirements of international buyers, the most recommended practice is to conduct multi-standard testing. Understanding these differences empowers brands to make informed decisions, ensure product quality, and avoid costly non-compliance issues.

FAQs

Q1: What is the most common color fastness to washing standard worldwide?

A: ISO 105-C06 is the most common standard globally, particularly in Europe, Asia (outside Japan), and much of the international textile trade. However, AATCC 61 is mandatory and most common in the United States.

Q2: How is the color fastness to washing test method carried out?

A: A fabric specimen is stitched between adjacent fabrics and placed in a sealed stainless-steel can containing a specified detergent solution and, often, steel balls. The can is then rotated in a heated water bath inside a washing fastness tester for a set time and temperature. After drying, the specimen is evaluated for color change and the adjacent fabrics for staining using gray scales.

Q3: Why do test results differ between ISO, AATCC, and JIS methods?

A: The differences stem from variations in test parameters like the type of detergent, the liquor ratio (amount of solution per gram of fabric), the amount of mechanical action (number of steel balls), and the rotation speed. These factors create unique washing environments with different levels of abrasion and chemical action.

Q4: What equipment is used for washing fastness testing?

A: The primary equipment is called a washing fastness tester, launderometer, or wash wheel. It is a precision instrument consisting of a thermostatically controlled water bath that rotates a rack of sealed stainless-steel containers.

Q5: How do I choose the right color fastness to washing standard for my products?

A: The choice is determined by the destination market of your products.

- For the European Union and most international markets: Use ISO 105-C06.

- For the *United States: Use *AATCC 61.

- For *Japan: Use *JIS L 0844.

Always check the specific requirements of your buyer or retailer, as they may specify a particular test method and severity. For products sold globally, testing against all relevant standards is recommended.