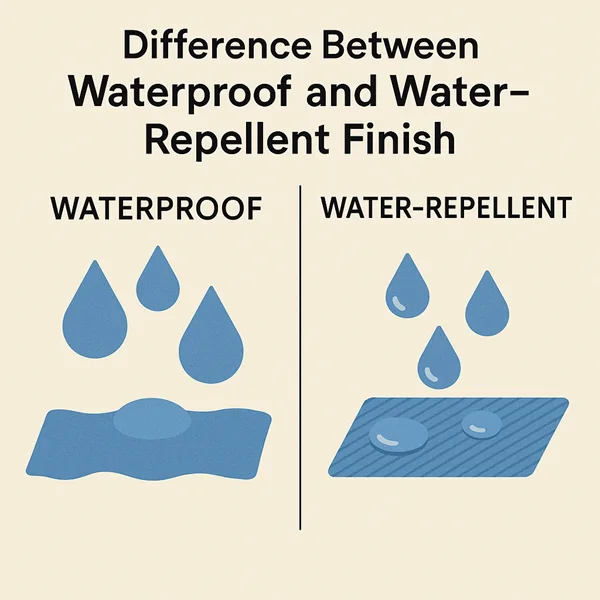

Difference Between Waterproof and Water-Repellent Finish

Though both of the terms seem quite the same. But there are technical differences between a waterproof and a water-repellent finish. How great it would be if any garment could keep you dry from any angry weather! To choose the right product, you need to know its basics. This article is all about the 7 Differences Between Waterproof and Water-repellent Finish.

So, if you want to know about the difference between waterproof & water-repellent finishes, then I would simply answer from the International Standards definition.

So, according to them, if the entry pressure of water is above 8.00 mm hydrostatic water column on any textile substrate, then you can term them as water-proof, but any textile material below this range is water-repellent. Before jumping into the differences between waterproof & water-repellent fabric, let’s know what they exactly mean.

What does Waterproof describe?

The waterproof finish is given with any hydrophobic substance of rubber, PU, or PVC that forms continuous layers on the surface of the fabric. To make it waterproof, any fabric needs to resist the passage of water into it. Interstices, seams, any type of opening in the material aren’t allowed.

The fabric labeled as waterproof should be impervious to water. With the help of seam sealing tape, all the seams connecting the outside to the inner side of the garment should be sealed so that no water can penetrate. These fabrics are not comfortable.

Nowadays, membrane-based products provide better waterproof performance. Though polyester and polyurethane membranes provide better results, they lose their efficiency with aging, UV radiation, and so on. GORE-TEX fabrics provide better waterproof performance.

If a product is given a waterproof finish, that doesn’t mean it will be waterproof forever. If the rain exposure of the waterproof material lasts for too long, it may permit the way of water to enter it.

What does Water repellent mean?

If the entry of water pressure is lower than 8 mm, then the fabric is called water-repellent. Water repellent fabric is also given a coating of a hydrophobic substance, but no continuous film is formed.

Water-repellent fabric is produced based on the idea of repelling or rolling off a liquid globule from the surface of the fabric. The surface contact angle is the one that is taken into consideration to make this fabric.

A water globule that makes an angle below 90 degrees can penetrate the substrate, whereas a contact angle above 90 degrees repels the water globule. It prevents the water molecule from spreading over the surface. So, the water drop is rolled on the fabric. This type of fabric can prohibit water passage for up to a certain time.

But with the high hydrostatic pressure, water gets into it. This is because the interstices are not sealed here. These fabrics are comfortable. To escape a watery shower without any discomfort, water-repellent fabrics are best.

Difference Between Waterproof and Water-repellent Finish

| Waterproof | Water repellent |

| Completely impervious to water or vapor phase | When the hydrostatic pressure is enough high, it can permit the passage of water |

| A continuous layer of hydrophobic substance is deposited on its surface. Rubber, PU, PVC etc materials are used for it | Hydrophobic substance is deposited on the surface but no presence of a continuous layer |

| No open pores | It has open pores in the structure |

| It is not breathable | It is breathable, air passes through open pores |

| The interstices of the yarns are also sealed | Interstices are not sealed |

| No penetration of water through any high hydrostatic pressure | Resist water globule to spread on the surface enabling it to roll on. |

| Example: Raincoat | Example: Can be used in apparel |

The Last Word

If you want to be relieved from light rain, then a water-repellent fabric is best. But for the heavy rain season, you definitely need a product that is waterproof.