Different Types of Cotton and Their Characteristics

Cotton is, by far, the most important textile fiber. There are different types of cotton fibers according to their staple length and plant varieties. With the plant varieties, their quality also varies. To produce top quality product, we need optimum quality cotton fibers. In this article, we will discuss different types of cotton fibers.

Cotton consists of cellulose, a polymer of glucose. Cellulose is the basic building material of all types of vegetation, and many different plants are sources of cellulose fibers. Different Types of Clothing and their Characteristics are discussed below:

How do we get cotton?

Cotton comes from the seed pod of plants in the Gossypium family cultivated in a number of subtropical climates. The fibers grow out of the seeds in the closed pod. In the initial phase, they form long, thin-walled cells filled with protoplasm.

Later, as the growth in length ends, the cell walls increase in thickness as rings of cellulose are deposited on the inner surface of the cell wall. When the pod or boll bursts, the cotton fibers, whose function is to aid seed transport in the wind, dry out.

Once the remaining protoplasm has evaporated, the cotton bolls are harvested mechanically and the fibers removed from the seeds by a process called ginning. This must be carefully controlled to avoid over-cutting of the fibers. Cotton ‘linters’, the short lint hairs not removed from the seeds by ginning, are also an important source of pure cellulose. Pressing the residual seeds gives cottonseed oil.

Different Types of Cotton

In different parts of the world, cotton fiber is grown with a wide range of growing conditions. As a result, there are many grades of cotton fibers around the world. They are of various qualities that vary widely in their characteristics and properties.

It is quite a difficult job to assess the quality of cotton. It requires great skill and experience. The quality of cotton is directly related to staple length and its characteristics, which is generally quoted to refer to any cotton.

Staple length is an assessment of fiber with respect to its technically most important length. In the case of cotton, staple length corresponds very closely with the most frequent length of the fibers when measured in a straightened condition.

Commercial Types of Cotton

Commercial cotton may be classified broadly into three categories. Here they are:

- Staple length 1-1 ½ inch (26-65 mm): Includes the fine, lustrous fibers that form the top quality cotton. The fibers are generally of 10 -15 micron diameter and are of 1.1-1.8 dtex (0.99-1.62 den).

Sea Island, Egyptian, and American Pima are in this category. These are high-category cotton. These cottons are difficult to grow. Their supply is comparatively low.

- Staple length ½ – 1 5/16 inch (12-33mm): This includes medium strength, medium luster cotton. This form the bulk of the world crop. These fibers are generally of 12-17 micron diameter and are of 1.4-2.2 dtex (1.26-1.98 den)

American upland and some Peruvian types fall into this category.

- Staple length 3/8 – 1 inch (9-26mm): This includes coarse and low-grade fibers. They are low in strength and have little or no luster. They are generally of 13-22 microns in diameter. They are of 1.5-2.9 dtex (1.26-1.98 den)

Many of the Asiatic, Indian, and some Peruvian cottons fall in this category.

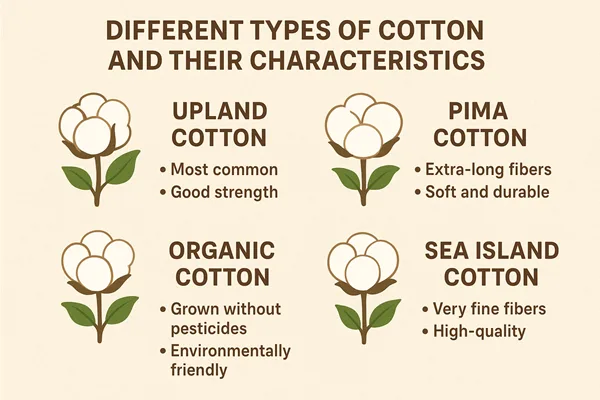

Types of Cotton depending on cotton plant varieties:

According to plant varieties, there are 4 types of Cotton. Here they are:

1. Gossypium hirsutum (Upland cotton)

Most widely this type of cotton is produced. 90% of the world’s cotton production is from this category. Cotton from Central America and the Caribbean Sea Island accounts for this category. These are exported to every location throughout the world. They are characterized by short-staple fiber that grows in any climate.

For making a quality fabric that all can afford, Upland is perfect. Especially in the US, this type of cotton mostly plants. Or you can say, 95% of fibers grow in American soil.

2. Gossypium Hirsutum (Acala cotton)

San Joaquin Valley Acala, the cotton type only produced by California. Among all of the upland cotton, this type is the highest quality cotton. This type of cotton gets benefits from the climate of San Joaquin Valley.

Acala cotton gets an extended growing period that increases yield. As a result, we get a finer product. This type of cotton is a bit costlier than American Upland cotton. This is due to its growing requirements.

3. Gossypium barbadense (Pima Cotton)

This type of cotton accounts for 8% of the world’s cotton production. These are more expensive than the previous one. This type of cotton consists of extra-long staple fiber. Textiles become softer and lustrous with this type of cotton.

South American cotton is from this category, they are exported throughout the world. Pima kind of cotton is from this category. Producers from China and India produce this cotton. So, what’s the benefit of using this extra-long staple fiber? It makes the fabric strong that makes it resistant to fraying, fading, wrinkling, and pilling.

4. Gossypium herbaceum (Egyptian cotton)

This type of cotton grows in longer bushes that can be considered as tree. This accounts for 2% of the world’s condition.

As like as Pima cotton, this type of Egyptian cotton is from extra-long staple fiber. This quality makes it also soft, supple, and vibrant in performance. So what is the difference between Egyptian cotton and Pima cotton? The main difference is in the cultivation process of cotton. Egyptian cotton is grown at hot and dry climate beside Neil River in Egypt. This type of cotton is exceptionally quality full.

5. Gossypium arboretum

This type of cotton is from Arabia and Africa. This accounts for not more than 2% of the world’s cotton cultivation.

An Overview of the Characteristics of Cotton

The word cotton comes from Arabic word “Katan”. It is called the king of fibers just only because of the characteristics of cotton. Cotton is the backbone of world’s textile market and it is also one of the most important and widely produced agricultural and industrial crops in the world.

Cotton is grown is about 80 different countries. The most important producers are China, USA, India, Pakistan, Uzbekistan, Turkey, Australia, Brazil, Argentina, and Syria. In this article we will discuss about the characteristics of cotton, types, physical and chemical properties of cotton.

Characteristics of Cotton

- Comfortable

- Light weight

- Non-elastic

- Good draping quality

- Feels soft

- Super absorbent

- Color retention capacity is good

- Dry cleanable

- Machine wash is possible

- Great strength

- Good cooling properties

- Dries fast

- Extremely shiny

- Moisture absorption is very good

- Very durable

- Wet fibers are more resistant

Morphological structure

Cotton contains 95% cellulose. High-grade, soft material with super absorbent quality- all these qualities are extremely suitable for cotton. Cotton is of different colors based on its origin. Cotton fiber length varies between 10 to 65 mm. American cotton has a white color, whereas Egyptian and Chinese cotton have yellowish and red-yellowish colors, respectively.

Under microscope the fiber appears to be-

- Ribbon like

- Kidney-shaped cross-section

- Natural convolution of the longitudinal view

- Having two ends

- Twisted in a spiral, tightly and regularly wrapped in high-end fiber

With sanforization and mercerization processes, the properties of cotton can be improved.

Polymeric structure of cotton

- Cotton is a cellulosic fiber.80-90% cellulose is in cotton, but oil, wax, protein, pectin, and some coloring content are also present. The polymer chain of cotton cellulose is linear.

- It is a polymeric sugar of a polysaccharide made up of 4000-9000 repeating cellobiose units, which consists of two glucose units connected to each other by 8-ether linkages.

- The number of repeating units of a polymer chain is called the Degree of Polymerization (DP).

- If 5000 repeating units stay in a polymer chain, then its Degree of Polymerization is 5000.

Grading & Classification of Cotton

The word Grading means the rating of cotton according to the quality parameters of cotton. Cotton is classified by grading, and it is done according to length, fineness, strength, color, luster and impurities. This division is done in a different way according to the production land.

Different grading systems

| American | Indian | Egyptian |

| Middling fairStrict Good MiddlingGood MiddlingStrict MiddlingMiddlingStrict Low MiddlingLow MiddlingStrict Good OrdinaryGood Ordinary | Super ChoiceChoiceSuper FineFineFully GoodGoodFully Good Fair | Extra FineFineGoodGood FairFair |

Properties of different cotton fibers with the Spinning limit

| Origin of Cotton | Fiber length (mm) | Micronaire (MIC) | Diameter (mm) | Spinning Limit (Ne) |

| Sea Island | 49-50 | 3.0-3.2 | 0.016 | 200 |

| Egyptian | 38-44 | 3.0-3.2 | 0.017 | 200 |

| American | 25.4-38 | 3.0-3.5 | 0.018 | 70 |

| CIS | 25.4-33 | 3.4-3.8 | 0.020 | 70 |

| Indian | 20.5-30 | 3.5-4.5 | 0.021 | 40 |

| China | 20.5-28 | 3.5-4.5 | 0.021 | Coarse |

| Pakistan | 15.5-25.4 | 4.0-4.8 | 0.021 | Coarse |

General Physical & Chemical Properties of Cotton Fiber

- Fiber Length: Varies from 10-65 mm

- Fiber Strength: Strength is varied 24-32 gm/tex

- Fineness: The value varies 3-6

- Maturity ratio: varies from 0.7-0.9

- Color: Light yellow or brown

- Moisture Content: 8.5%

- Gravity: 1.48 – 1.51 g/cm3

- Effects of Acids: Cotton fibers are weakened by cold weak dilute acids and degraded by strong acids.

- Effects of Alkali: Unaffected or undamaged by alkaline solution

Types of Cotton Yarns

- 100% Cotton

These yarn has 100% cotton fibers. Garments containing 100% cotton yarn has ability to absorb sweat immediately. It has cooling properties. So, this is used in hot weather extensively. But blends of cotton is cheap than this. For maintaining high quality, 100% cotton is used to make garments or apparel.

- CVC

CVC stands for chief value cotton. A blended yarn having a higher percentage of cotton as compared to that of polyester is called CVC yarn. For example: Cotton: Polyester 70: 30. Pricing of CVC is still too high.

- PC

Yarn produced by blending cotton and polyester fibers. The maximum part of these yarns are polyester. The yarn contains more than 50% of polyester. The rest is cotton.

- TC

TC stands for Terelyne – Cotton. This is also made by blending of cotton and terelyne fibers. But in this case, the higher amount used is polyester fibers and the rest portion is cotton fibers. TC yarn is used for making apparel most of the time. This provides the soft and cool feel of cotton to the user.

Identification of cotton fiber

There are different tests that could be used for the identification of the cotton fiber. It is suggested to combine at least two or more different methods to reach an acceptable and reliable conclusion in practice.

- Feeling test: Unresponsive, smooth, and a soft hand to human skin, feels good against the skin.

- Burning test: The reaction of fibers to heat from an open flame is a useful guide in the identification of fibers. Non-melting, non-burning. Smells like paper burning. The smell of cotton burning is like that of paper burning because paper is also a cellulosic material.

Some technical tests are required for detailed identification

- Microscopic identification

- Chemical test

- Coloring with dyestuffs

- Solubility test: Cotton is easily dissolved by H2SO4

- Staining

End use

- Apparel Clothes

- Home textiles to Industrial textiles

Wrap Up!

The versatility of cotton is huge. Its uniqueness makes it the most popular fiber ever. The characteristics of cotton make it more preferable to all. Cotton and Viscose contain pure cellulose among all fibers. Other natural fibers containing cellulose also contain some other constitutional materials. Although cotton and viscose are almost pure cellulose, they have quite different physical properties because of their distinctive morphologies and molecular arrangements.

Even though cotton and viscose fibers can be dyed with the same types of dyes, using similar methods, their dyeing characteristics are different.

- You may love to read: Physical and Chemical Properties of Cotton Fiber