Ergonomics in the Garment Manufacturing Industry

Ergonomics in the Garment Manufacturing Industry

Ergonomy comes from the Greek words ergos and nomos and implies work laws. Scientists are concentrating increased focus on this field of study that combines research on human anatomy, physiology, biomechanics, and industrial engineering. In short, Ergonomy is the study of how people interact with their environment at their workplace. This article is about the importance of Ergonomics in the Garment Manufacturing Industry.

Ergonomics

Ergonomics is the study of the relationship between a person and their work environment. The objective is to adapt to the workplace for the worker in order to decrease the risk of injury and improve the link between the worker and their environment.

Advantages and Disadvantages of Ergonomics in the Workplace of Apparel Industry:

Ergonomy looks for ways to optimize the relationship between workers and the environment they are working in thus trying to improve the workplace environment to pave the way for better job performance and textile and apparel productivity.

It is understandable that a worker working in a workstation cannot attain the best performance because of the fact that the workstation is poorly designated. If the worktable is too high or too low, he will not attain the best motion and the work may prove to be tiresome. Even poor light can seriously disrupt the work efficiency of a sewing operator.

Besides, sewing line workers are engaged in special types of work which is repetitive in nature. Such type of work leads to a type of disorder of body parts which has come to be known as Cumulative Trauma Disorders or Repetitive Motion Disorders. These are very painful diseases that may lead to body or body parts dysfunction.

The factors that induce such disorders include the following:

- Continuous work repetition,

- Posture (wrong manner of sitting or standing during work for long hours),

- Pace,

- Force,

- Vibration.

Role of Ergonomics in the Workplace of Apparel & Textile Sector:

1. Human Factors:

Ergonomy seeks ways and means to fit the person to the job or vice versa. It also studies human dimensions (anthropometry) so as to be able to design tools, equipment, and workstations suitable for the individual so that he can use most of his physical and psychological ability in performing the job.

Environmental conditions including light, air, ventilation, and temperature seriously influence the workstations and as a result employee performance. Optimum conditions promote congenial working conditions and so productivity.

2. Job Design:

Sewing workers undergo rigorous types of repetitive work. Some workers make as many as 50 movements per minute with each hand. Such quick repetitive work takes a heavy toll on their health by causing weakness, fatigue; injury, etc. Working in sitting or standing conditions in static posture is vulnerable to such problems. Working in sitting or standing conditions has its own pros and cons. Sitting allows body weight to be distributed to the sitting device, easier muscle coordination, and easy hand manipulation but this allows to use limited body strength and control limited work area.

On the other hand, standing posture allows using higher body strength, and better control over the work area. However, sustained work in a standing posture puts heavy pressure on the legs and often leads to leg swelling. The better layout is one that allows workers to move between workstations. Such layouts also allow a sit & stand approach which is considered more health-friendly.

3. Workstation Design:

Workstations should be so designated that they fit the individual dimensions enabling him to work without any limitations on posture, pace, etc., and must be congenial to the work environment. Design features should include the height of the work surface (tabletop), seat height, elbow height, work area to be controlled,d etc.

Ergonomics in the Garment Manufacturing Industry

Awkward body postures are a major ergonomic concern in the garment industry. Awkward postures take the body away from a comfortable position, which reduces efficiency and increases the use of energy. Another major concern is static postures. Static means to hold in place, so these are postures where the body is held in one position for a long period of time. An example is when you work with your arms above shoulder height for long periods of time. These types of postures require constant muscle use for the time the body is held in the position. This reduces rest and recovery time, which leads to muscle tiredness. The following are recommendations that will help to reduce the risk of injury due to the above concerns.

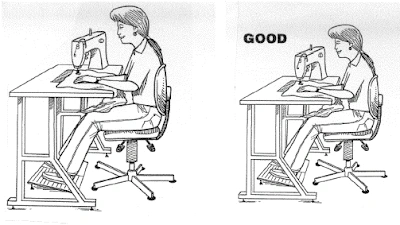

For seated and standing work, the height of the workstation should allow workers to function with elbows at 90 degrees. If the workstation is too low, the worker is forced to bend at the waist to reach the work being done. This puts stress on the lower back. If the station is too high, the worker is forced to lift their shoulders or move their elbows away from the body to reach their work. This puts increased stress on the shoulders which may lead to injury.

During seated work, if good back support is not present or used, static postures occur which results in constant use of the back muscles. It is important to adjust the workstation in order to allow the worker to use the backrest. Need adjustment of the worker’s chair to allow duties to be performed with their bodies in comfortable positions, very much important thing in ergonomics. The workstation and chair should be positioned so that the worker’s knees, hips, and elbows are at 90 degrees, which will reduce stress on the body. There should also be enough space to allow the worker to change their sitting position throughout the day.

Static postures can also occur during standing work. If the worker stands in one position for long periods of time, the muscles of the back and legs will be constantly activated. This can lead to increased fatigue and decreased blood circulation to the legs. During the day, workers should try to walk around to allow their blood to flow. As well, workers should try and sit for short periods of time while working to give their leg and back muscles a rest.

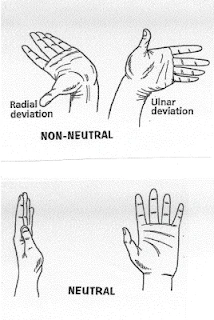

Awkward wrist postures are one of the major causes of cumulative trauma disorders (CTD) such as carpal tunnel syndrome (CTS), tendonitis, and muscle strains. Awkward wrist postures are those that take the wrist away from the neutral position. The neutral position is when the hand is in line with the forearm. The workstation should be adjusted and the worker educated on awkward wrist postures, their harmful effects, and the signs and symptoms of CTD’s.

Workers should not constantly work with their arms above shoulder level. Work above the shoulders increases the use of the shoulder muscles. With this constant use, the muscles do not have time to rest and thus tire more rapidly. The majority of work should be done between knuckle height and shoulder level.

Workers should try not to twist their upper bodies when placing objects beside them. By keeping their feet in place and only moving their upper body, workers are putting large stresses on their backs, which may lead to injuries. Workers should move their feet, instead of twisting at the waist, in order to face the area where the object is going to be placed. If the worker is sitting, they should try to swivel in their chair, instead of twisting their upper body.