Face to Face Layout System in Garments Sewing Line: Advantage & Disadvantage

Face to Face Layout System in Garments Sewing Line, Its Advantages and Disadvantages

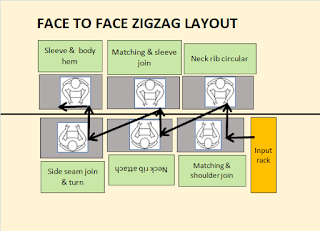

The layout is the first thing to do if you want to start a sewing line. The sewing layout is different for every individual style. A permanent layout setting is a key thing for saving manpower, machines, and transportation handling systems. We are discussing Face to Face Layout Systems in Garments Sewing Lines, and Its Advantages and Disadvantages.

Sewing Line Layout

We did a case study on the garment sewing line. The study was two Layout systems of garment manufacturing. One is the Straight Line layout which is currently running in our facility and another is the proposed Layout ‘Face to Face Layout’. If you want to know about these two Layout systems of the sewing process, here this article is only for you.

Objective:

- To compare the running & proposed layout system

- To Highlight the advantages & disadvantages of the proposed layout system

- Explore the benefits of this layout system.

Straight Line Layout System Vs Face to Face Layout System:

| Category | Straight Line Layout system | Face to Face Layout system |

| Type of layout | Straight-line layout-Overhead material movement | Need width extension- 7 feet 2 inches |

| Sitting arrangement | Wooden stool without any backrest | Rotating chair with backrest |

| No. of machine | 26-28 machine/line | 38-40 machine/line |

| Line width | Conventional- 6 feet 8 inches | No bundle-keeping basket, material movement through side table |

| Wire arrangement | Conventional electrical connection as well as lighting | Re-arrangement as per line layout |

| Air compressor | Conventional air compressor line | Re-arrangement as per line layout |

| Bundle keeping basket | Not necessary as material movement through the side table | Need bundle keeping basket for every workstation |

| Machine width extension | Manually done or there are some machines with auto trimming facility | Need machine width extension through wooden pallet as there will be no side table |

| Thread trimming | Need auto trimming facility in every machine so that use of assistant operator becomes optimal | The bundle size need to resize, 10 to 20 PCs |

| Bundle size | Big bundle size, typically 50 to 60 PCs | The bundle size needs to be resized, 10 to 20 PCs |

| Kanban/andon boards | No kanban/ andon boards in line & front | Need kanban/ andon boards in line & front |

Advantages of Straight Line layout system Vs Face to Face Layout system:

| Sl. | Category | Straight Line Layout system | Face to Face Layout system |

| 1 | Tracking & monitoring | Difficult to tracking & monitoring production & quality | Easy to tracking & monitoring production & quality |

| 2 | Utilization of machine | 26-28 machine/line in conventional | more 10-12 machine can be used inline |

| 3 | Transportation time | Material transportation time is more | Material transportation time is less |

| 4 | Product type | Any kind of item in the production line | Basic/ small items in a production line |

| 5 | Layout doubling | Single item run in production line | Two basic items can be run in production line |

Disadvantages of Straight Line Layout system Vs Face to Face Layout System:

| Sl. | Category | Straight Line Layout system | Face to face Layout system |

| 1 | Garments handling | Limited product types as long/big garments handling the issue | Only basic/ small items can be handled |

| 2 | Product variation | Any kind of product can be run online | Limited product type as long/big garments handling the issue |

Expected result:

- Transportation time reduction

- Ergonomically designed work-station

- Proper tracking of production & quality

- Visual management on the production floor