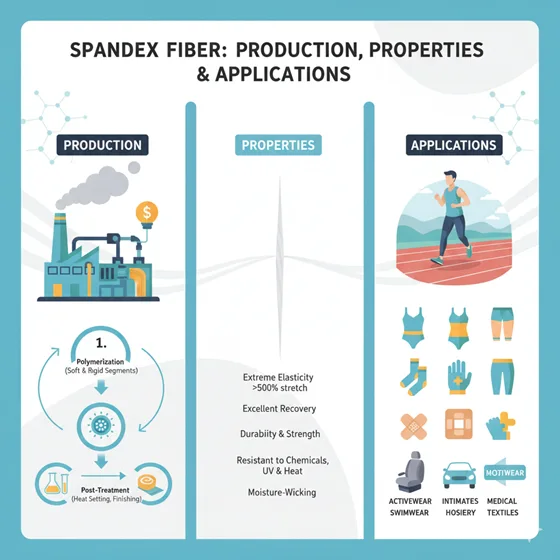

Production, Properties and Applications of Spandex Fiber

Spandex fiber, also known as elastane or Lycra, is a synthetic fiber widely used in the clothing and textile industries. It is a stretchy, lightweight, and durable fabric known for its exceptional elasticity, comfort, and flexibility. In this article, we will explore what spandex fiber is, how it is made, its properties and characteristics, and its various applications in different industries

Spandex fibers are a versatile and popular material used in a variety of industries, including apparel, medical, and automotive. It is a unique material known for its exceptional elasticity and extensibility, making it an ideal choice for applications requiring flexibility, durability, and comfort.

Production of spandex fiber

Spandex fiber production involves several steps, including raw material preparation, spinning, drawing, and texturing.

Step 1: Preparing the raw materials

The first step in the production of spandex fiber is the preparation of raw materials. The two primary raw materials used in the production of spandex fibers are polyurethane and a soft-segmented copolymer. Polyurethane is a long-chain polymer that provides elasticity and strength to the fiber, while copolymers provide softness and flexibility.

Step 2: Spinning

After the raw materials are prepared, they are melted and mixed together to form a spinning solution. The spinning solution is passed through a spinneret, a device with several small holes, to produce a continuous fiber. The fiber cools and hardens while passing through the coagulating bath.

Step 3: Drawing

After the fiber is formed, it is stretched or stretched to increase its strength and elasticity. A series of fibers is passed through.

Of rollers, each rotating at a different speed, which stretches the fiber several times its original length. Stretching aligns the polymer chains, increasing the fiber’s strength and elasticity.

Step 4: Texturing

After drawing, the fiber is textured to give it a more natural look and feel. The fiber is heated and twisted, creating a creamed texture. The texture helps the fiber adhere better to other fibers in the fabric and improves its overall strength and flexibility.

Properties of spandex fiber

Spandex fiber has several properties and characteristics that make it unique and useful in various applications.

Elasticity and extensibility

Spandex fiber can stretch up to 600% of its original length and still return to its original shape without losing its elasticity. This makes it an ideal material for applications that require flexibility and stretchability, such as sportswear, medical textiles, and underwear.

Durability and strength

Spandex fiber is a durable and strong material that can withstand frequent use and washing without losing its shape or elasticity. It is resistant to wear and tear, making it ideal for use in high-performance applications.

Lightweight and comfortable

Spandex fibers are a lightweight and comfortable material often used in clothing and sportswear. It is soft to the touch and provides a comfortable fit that moves with the wearer.

Resistant to moisture, heat, and chemicals

Spandex fiber is resistant to moisture, heat, and chemicals, making it suitable for use in a variety of environments. It can withstand exposure to sweat, oil and other substances without losing its elasticity or strength.

Applications of spandex fiber

Spandex fibers are used in a variety of industries, including textiles and clothing, medical, sports, automotive, and furniture. Some common applications of spandex fiber.

Textile and apparel industry

Spandex fibers is commonly used in clothing, such as leggings, tights, and other stretchy garments. It is also used in sportswear and underwear, providing flexibility and comfort.

Medical Textile and the sports industry

Spandex fibers are used in medical textiles, such as compression stockings and braces, to provide support and comfort. It is also used in sportswear, providing flexibility and mobility for athletes.

Automotive and Furniture Industry

Spandex fibers are used in the automotive and furniture industries, providing flexibility and durability in seat covers and upholstery.

Advantages of spandex fiber

Flexibility and Stretchability:

The biggest advantage of spandex fiber is its high degree of flexibility and stretch ability. This makes it an ideal material for athletic wear, swimwear and other garments that require freedom of movement.

Comfort:

Spandex fibers is known for its comfort and softness, making it an excellent choice for close-to-the-skin clothing.

Durability:

Spandex fibers is highly resistant to wear and tear, making it an excellent choice for clothing and other materials subject to heavy use.

Elasticity:

Spandex fibers has excellent elasticity, meaning it can hold its shape even after repeated stretching and washing.

Moisture-wicking:

Many spandex blends are designed to wick moisture away from the body, making it an excellent choice for athletic wear and other high-performance applications.

Disadvantages of spandex fiber

Non-biodegradable:

Spandex fiber is not biodegradable, meaning it can take hundreds of years to break down in landfills.

Environmental Impact:

The production of spandex fibers can have a significant environmental impact, including the use of non-renewable resources and the release of pollutants into the air and water.

High cost:

Spandex fibers is generally more expensive than other types of synthetic fibers, which makes it less accessible for some applications.

Heat Sensitivity:

Spandex fibers is sensitive to high temperatures and can be easily damaged by heat, making it unsuitable for some applications.

Limited breathability:

Spandex fibers is not known for its breathability, which can make it less comfortable in hot and humid environments.

FAQs: Topic-related questions and answers

Is spandex fibers safe for sensitive skin?

Yes, spandex fibers is safe for sensitive skin and is often used in medical textiles.

Can spandex fibers be recycled?

Yes, spandex fibers can be recycled, but the process is complicated and not widely available.

How to care for clothes made of spandex fibers?

Garments made of spandex fibers should be washed in cold water and dried on low heat to avoid damaging the fabric.

Is spandex fiber environmentally friendly?

Spandex fibers are not considered an environmentally friendly material because it is made from non-renewable resources and are difficult to recycle.

Can spandex fiber be used in outdoor applications?

Spandex fibers are not suitable for high-temperature applications, so they may not be the best choice for outdoor use in hot climates.

Conclusion

Spandex is a very important and useful textile fiber. Because of its elastance properties, spandex became a very special textile fiber that can be used in shirts, pants, T-shirts, and blended with any textile fiber. We discussed the Production process, Properties, and Applications of Spandex Fiber.