What do You Mean by 2.5 AQL in Garments Inspection?

What do You Mean by 2.5 AQL in Garments Inspection?

2.5 AQL is a common term in the garment industry. It should be audited before shipping. In order to check garment defects, a quality inspection must be carried out. The inspection should be based on the 2.5 AQL System. In addition, most of the buyer wants the inspection will be 2.5 AQL. We can easily understand 2.5 AQL systems in garment inspection in the following. In this article, we discuss about What do You Mean by 2.5 AQL in Garments Inspection.

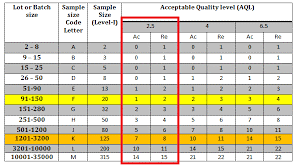

AQL: AQL means “Acceptable Quality Level”. Every product has a quality level. We cannot measure without quality level. So, we must measure the status of the product. Normally, we measure many products through the inspection method. There are many inspection methods used by different buyers in the garment sector but 2.5 AQL is one of the most popular inspection methods in the apparel sector. Moreover, we have to ensure the quality of products by 2.5 AQL inspection methods. Meanwhile, first, the 2.5 AQL table was developed & used by the American military. Now, we are using this table in garments inspection in the apparel sector. AQL inspection requires a Final Inspection Process in The Garments Industry.

2.5 “Acceptable Quality Level” is the simple table-to-cheek inspection. It is not difficult & critical. We must find out how many quantity & defect garments. Normally, we inspect major defects by 2.5 AQL system.

Example:

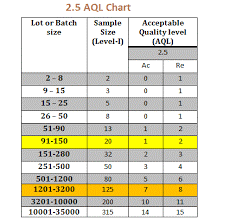

Yellow Column:

Here, the lot size given is 91-150. If we have a quantity of 100 pcs then we need to inspect the garments with 20 pcs sample. According to 2.5 AQL we must cheek the 20 pcs garments out of 100 pcs.

According to 2.5 AQl table chat, Ac means “Accept”. If we get defective garments 1 or less than 1 out of 20 pcs it will be “Accept” or “Pass” in this inspection. On the other hand, Re means “Reject”. If we get defective garments 2 or more than 2 out of 20 pcs it will be “Reject” or “fail” in this inspection.

Brown Column:

Here, the lot size given is 1201-3200. If we have a quantity of 1500 pcs then we need to inspect the garments 125 pcs sample. According to 2.5 AQL we must cheek the 125 pcs garments out of 1500 pcs.

According to the 2.5 AQl table chart, Ac means “Accept”. If we get defect garments 7 or less than 7 out of 125 pcs it will be “Accept” or “Pass” in this inspection. On the other hand, Re means “Reject”. If we get defective garments 8 or more than 8 out of 125 pcs it will be “Reject” or “fail” in this inspection.

- You may love to read: AQL Chart for Sampling & Acceptance Level in Garments Quality Inspection.