How to Calculate Garments Costing for Polo Shirt?

Costing and consumption of apparel export order is the main tasks for the apparel merchandisers. Both works are not too tough if an apparel merchandiser follows the actual method for those. In another article, I have shared an article about how to calculate apparel costing for a T-shirt, but now I have presented here the actual fabric consumption and apparel costing method for a knitted polo shirt.

The method of Garments Costing for a Polo Shirt is very easy to calculate. Polo shirts are made of knit fabric, so we need to know the price of used fabric. Cutting, Sewing, finishing, and trimming costs are included in the manufacturing cost.

Polo Shirt Costing and Consumption Method in the Apparel Industry:

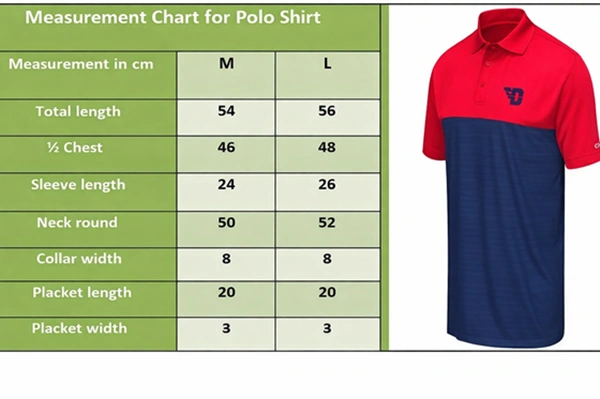

Find out the price of a Polo T-shirt by following the given measurement chart and apparel specifications:

| Polo Shirt Specifications | |

| Style of Polo Shirt | Polo T-shirt with flat knit collar |

| Fabric | Body – 95% Cotton single jersey and 5% Lycra |

| Collar – (2×2) Rib, 100% cotton | |

| G.S.M | 180 G.S.M for body fabric and 220 for collar |

| Color | Light green |

| Print at chest | |

| Size Ratio | S:M:L:XL = (1:1.5:2:0.5) |

| Quantity of Order | 20000 pcs |

Solution:

Fabric Consumption Calculation or Apparel Weight Calculation:

To calculate fabric consumption for polo shirt, we will apply the following formula:

Apparel weight calculation or fabric consumption (Single jersey fabric),

[{T.L + S.L + (2× H.A) + (2 × S.A)} × (1/2 Chest + S.A)] × G.S.M × 2

= ……………………………………………………………………………….… … (A)

10000

Again,

Flat knit collar weight calculation (Rib fabric),

{Neck round × (Collar width + S.A) × G.S.M}

= …………………………………………………… ……….. (B)

10000

N.B: Flat knit collar is single layer fabric. So, no need to multiply by 2.

Again,

Flat placket weight calculation (Single jersey fabric),

{(Placket length + S.A) × (Placket width + S.A) × G.S.M × 3}

= ……………………………………………………………..……… …….. (C)

10000

N.B: For placket, there is 3 or 4 fold. So, it is multiplied by 3 or 4.

Where,

T.L is stands for Total length.

S.A stands for Seam allowance.

H.A stands for Hem allowance.

S.L stands for Sleeve length.

Fabric consumption calculation for middle size i.e., L Size:

Let,

Seam allowance =2cm,

Hem allowance = 2cm,

So,

From equation A, we get,

[{56+26+ (2×2) + (2×2)} × (48+2)] ×180×2

= ……………………………………………………….

10000

= 162gms

= 0.162kg

Again,

From equation-B, we get,

{(52 × (8+2) ×220}

= ……………………………..

10000

= 11.44gms

= 0.012kg

Again,

From equation- (C), we get,

{(20+2) × (3+2) × 180 × 3}

= …………………………………..

10000

= 5.94gms

= 0.006kg

So,

L size fabric consumption (for single jersey) is,

= (0.162+0.006) kg

= 0.168kg

Again,

L size fabric consumption (for 2×2 rib fabric) is 0.012kg

Calculation of Fabric Cost Per Kg:

| Parameters | Costing for S/J | Costing for Lycra | |

| Yarn price per kg | Cotton 95% = Rs. 240×95%= Rs. 228 | Rs. 268.00 | Rs. 190.00 |

| Lycra 5% = Rs. 800×5% = Rs. 40 | |||

| Knitting rate per kg (S/J Lycra) | Rs. 15.00 | Rs. 14.00 | |

| Dyeing rate per kg | Rs. 60.00 | Rs. 60.00 | |

| Printing rate per kg | Rs. 0.00 | Rs. 0.00 | |

| Compacting rate per kg | Rs. 6.00 | Rs. 6.00 | |

| Heat setting rate per kg (Synthetic fabric) | Rs. 6.00 | Rs. 0.00 | |

| Total | Rs. 355.00 | Rs. 270.00 | |

| Process loss (10%) (+) | Rs. 35.50 | Rs. 27.00 | |

| Fabric cost per kg | Rs. 390.50 | Rs. 297.00 | |

Cost of Fabric Calculation per Pc Apparel:

Cost of fabric per apparel,

= (Apparel weight or fabric consumption × Fabric cost per kg)

For single jersey fabric,

= 0.168kg × Rs. 390.50

= Rs. 65.60

For (2×2) Rib fabric,

= 0.012kg × Rs. 297.00

= Rs. 3.56

Total fabric cost stands at,

= Rs. 65.60 + Rs. 3.56

= Rs. 69.16

Apparel Costing Format for Knitted Polo Shirt:

The cost of the knitted polo shirt is calculated as in the below:

| SL No. | Particulars | Costing | ||

| 01 | Cost of fabric per pc apparel | Rs. 67.30 | ||

| 02 | Cost of making cost | Rs. 15.00 | ||

| 03 | Chest printing | Rs. 8.00 | ||

| Trimmings and accessories | Main label | Rs. 0.60 | Rs. 5.55 | |

| Wash care label | Rs. 0.30 | |||

| Button | Rs. 1.00 | |||

| Pouch or Poly bag | Rs. 1.00 | |||

| Hang tag | Rs. 0.50 | |||

| Insert card | Rs. 0.80 | |||

| Barcode sticker | Rs. 0.60 | |||

| Hologram sticker | Rs.0.75 | |||

| 04 | FOB + Packing (Rs. 1 per 30gms of apparel) 180gms/30gms = Rs. 6 | Rs. 6.00 | ||

| 05 | Sub total | Rs. 101.85 | ||

| 06 | Overhead cost (10%) (+) | Rs. 10.20 | ||

| 07 | Sub total | Rs. 111.05 | ||

| 08 | Rejection cost (3%) (+) | Rs. 3.33 | ||

| 09 | Sub total | Rs. 114.38 | ||

| 10 | Profit percentage (15%) (+) | Rs. 17.15 | ||

| 11 | Sub total | Rs. 131.53 | ||

| 12 | Commission of agent | Rs. 0.00 | ||

| 13 | Insurance cost | Rs. 0.00 | ||

| 14 | Apparel price (FOB) in Rs. | Price in Rs. 131.53 | ||

| 15 | Apparel price (FOB) in US ($) | Price in US ($) = $3.0 | ||

| 16 | Apparel price (FOB) in Euro. | Price in Euro = E 2.09 | ||

Conclusion

How to calculate the Methods of garment costing for a Polo Shirt is important. Knowing eveything of it will keep ahead during the negotiation with the buying house.