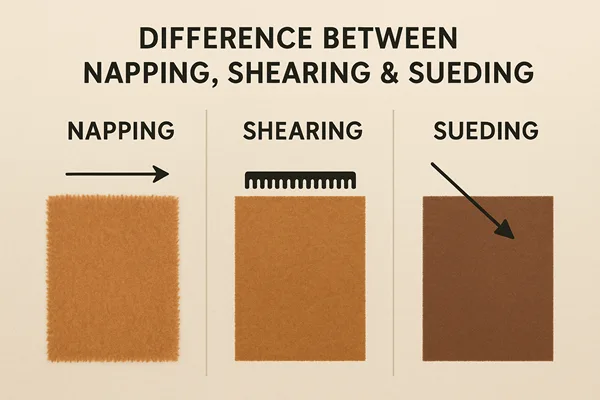

Difference Between Napping, Shearing & Sueding

Napping, shearing, or sueding, whatever you think of, all are used to raise fibers from the fabric surface. These are all finishing types to improve the softness and comfort of the fabric. There are some basic differences between napping, sueding, and shearing. The terms napping, shearing, and sueding are all fabric textile finishing processes that affect the surface texture of textiles, primarily for aesthetics and tactile qualities. Here’s a clear breakdown of the differences among them:

Napping

Napping is done to get a deep hairy surface. This process involves passing the fabric over revolving cylinders covered with fine wires with small hooks on the ends. Flannelette, wool flannel, velours, fleeces, etc, are examples of the napped sample.

Shearing

Shearing is a process by which protruding fibers from the surface of a fabric are cut the raised nap to a uniform height. The fun fact is the machine is operated like a lawnmower. There is a spiral cutter that rotates against a stationary blade and cuts off any material protruding from the fabric surface. The main purpose of shearing is to smooth the fabric surface by cutting raised fibers to a uniform height. And the napped fabrics are sheared to give an even pile height. Example fabrics: Velvet, corduroy, sheared fleece.

Sueding

Sueding is done to cut surface fibers and produce a fuzz, a suede-like surface on the fabric. Sueding can be carried out in both the dry and wet states. Example fabrics: Microsuede, peach-finished polyester, sueded satin.

4 Difference Between Napping vs Shearing vs Sueding

| Napping | Shearing | Sueding |

| Fibers are raised from the fabric surface by using wire-covered rolls to “dig out” individual fiber ends to the surface. | The raise fibers are cut to smooth out the fabric. | Fabric is abraded with sandpaper covered rolls (emery cloth) |

| Speed, tension of rollers play an important role. | Shear revolver, blade, cloth rest design and raising brush equipment should be considered. | Grit of sandpaper, speed of roll, speed of fabric plays an important role. |

| Produce warmth and soft hand. | Improved pilling resistance & smooth surface or patterns. | Improves softness and hand |

| Pile height greater than that obtained from sueding. | Uniform pile height | Produces low pile on fabric |

Final Words

The above three processes are done as a finishing step to pluck up fibers from the top of the surface. But they don’t provide the same effect.