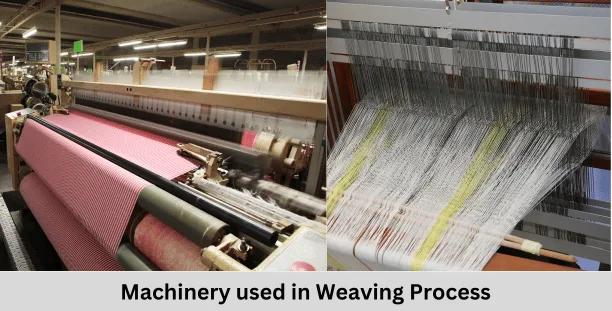

List of Machinery Used in Weaving Process and Their Functions

List of Machinery Used in the Weaving Process and Their Functions in the Textile Industry

There are various types of fabric produced in the textile industry, including woven fabric, knitted fabric and non-woven fabric. In this article, we have listed all the machines that are used in woven fabric manufacturing. We all know that, before weaving any fabric, there are some preparation processes including winding, warping, sizing, drafting, denting, and finally weaving. The machines that are normally used in these processes are listed here according to the process section. This article is about the List of Machinery Used in the Weaving Process and Their Functions.

List of Machinery Used in the Weaving Process

Weaving is a process by which fabric is produced by the interlacing of warp and weft thread. This is the 2nd process of textile product processing; the first is yarn manufacturing, then weaving. The weaving process produces grey woven fabrics. A number of machines are used to weave the fabric. Weaving Machines List:

- Winding Machine

- Creeling Machine

- Warping machine

- Sizing machine

1. Winding machines

Winding is the process of transferring yarns from a ring, bobbin, hank, etc., into a suitable package. There are different types of machines used in the winding process of fabric manufacturing, which are listed below separately:

According to the winding process, two types of winding machines:

- Precision winding machine.

- Non-precision winding machine

According to Drive:

a. Direct drive winding machine.

b. Indirect drive winding machine

Winding for weft yarn:

a. Ordinary pirn winding machine (For conventional loom)

b. Automatic pirn winding machine (For modern loom)

c. Cop winding machine

Functions of a winding machine:

a. Transfer yarn from one package to another suitable package

b. Removing yarn faults like hairiness, neps, slubs, and foreign matter

c. Cleaning the yarn

2. Creeling Machine

3. Warping machine

In the textile weaving industry, the warping process means the parallel winding of warp ends from many winding packages like cone or cheese onto a common package (warp beam). The machines used in the warping process are-

1. High-speed warping machine

2. Sectional warping machine

Functions of warping machine

a. Converting the yarn package into a warper beam of the required width.

b. Modifying the faults like thick place thin place.

c. Winding the predetermined length of yarn.

d. Accelerating the next process.

4. Sizing machines

Sizing is the process of applying a protective adhesive coating upon the yarns surface. There are some key advantages due to sizing the yarn like it increases elasticity of yarn, yarn strength, weight of the yarn, smoothness and frictional resistance. The machine which are used in sizing process are-

a. Slasher sizing machine.

b. Ball warp sizing machine.

c. Hank sizing machine

Functions of sizing machine

a. Increasing the weave ability of warp yarn.

b. Increasing the tensile strength or breaking strength of cellulose yarn.

c. Increasing smoothness, the elasticity of yarns.

d. Imparting adhesion.

Loom Machines and their feature

Loom is the contact point of the whole process of fabric production. Ginning, opening, carding, spinning, winding, warping, sizing, and beaming are done before the weaving process. The machines that are used in the weaving loom process to make woven fabric are listed in below. The device used for producing woven fabric is called the loom. This is the main process for clothing production. A loom is a mechanism of weaving yarn or thread into textiles. Different types of loom :

1. Handloom

2. Power loom

1. Handloom types:

i. Primitive loom

ii. Pit loom a) Throw shuttle b) Fly shuttle

iii. Frame loom a) Throw shuttle b) Fly shuttle

iv. Chittaranjan loom

v. Haterslay loom

Features of handloom weaving:

a. The operating system is manual

b. Shedding is done by paddle. Picking, beating done by hand

c. Production is less in handloom

d. Running speed is slow

e. Check and striped fabric are produced

2. List of Power looms used in weaving:

i. Air jet loom

ii. Water jet loom

iii. Rapier loom

iv. Projectile loom

v. Multiphase loom

Features of power loom:

- This is operated by power

- Shedding and picking is done automatically

- High production

- High running speed

- One-color fabric is produced.

Modern Loom or Shuttle Less Loom Machine List:

Modern loom or shuttle less loom has classified into four categories, such as-

- Rapier loom machine,

- Multiphase loom machine,

- Projectile loom machine,

- Jet loom machine.

Rapier Loom Machine List:

It has two categories, including-

- Single rapier loom machine,

- Double rapier loom machine.

Multiphase Loom Machine List:

It also has two categories, including –

- Plain loom machine,

- Circular loom machine.

Jet Loom Machine List:

Jet loom is classified into two types. These are-

- Water jet loom machine,

- Air jet loom machine.

Above all are the List of Machinery Used in the Weaving Process and Their Functions in the Textile Industry, or we can tell list of machineries used for woven fabrics manufacturing.