Types of Calendering Process in Textile Industry

Calendering, the temporary finish is given to the fabric in the presence of high temperature, heavy pressure, and a suitable degree of dampness. No matter what, you want a smooth, glossy, silky touch and highly lustrous fabric; it is easy to achieve with the calendering process. In this article, we cover different types of calendering processes. If you are interested in it, just go through the content. This article is about the Types of Calendering processes in the Textile Industry.

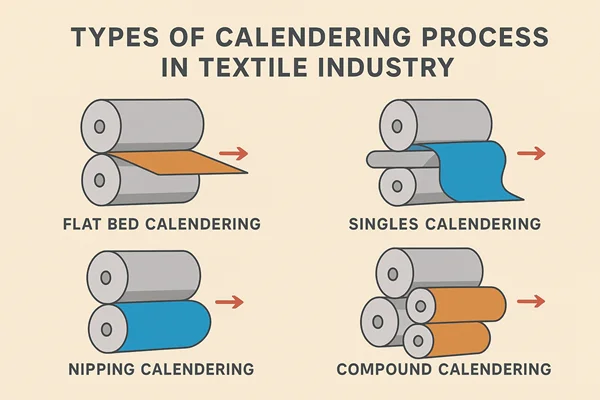

With the simultaneous action of temperature, force, and moisture, the surface of the textile substrate is modified. This simultaneous action is called calendering. Calendering in textile may simply be achieved while passing the textile substrate between two heated drums or rollers. The rotation speed and pressure of the heated drum may be varied according to need. Types of Calendering Process in the Textile Industry in the following:

There are different types of textile finishes. Among them, calendaring is a mechanical finishing process. You can definitely beautify your fabric by calendaring. Without any further due, let’s find out the calendaring process. Wanna know how it’s done? The effect of calendering is achieved by ironing. Ironing makes the fabric crease-free. Not only calendaring process make the fabric crease-free, but it also does a lot. Types of Calendering Process in the Textile Industry.

Different Types of Calendering Process

Different types of finishes are carried out in the factory to make the fabric marketable. But Calendering process, the temporary finish is the most common in the textile industry. Find out the 6 types of calendering process below!

1. Swizzing Calendering

- It is a British term

- Denote that fabric runs through all the nips and then either plaiting or batching

- Usually consists of 7-10 bowls

- All bowls rotate at same speed

- Softening and filling agents should be applied to produce lustre

- It gives close inter stiches, smooth appearance and gloss without high glaze (which we get from friction calender)

- Smoothness and lustre are increased with the increase of bowl temperature (150-180°C)

Advantage

- Uniform calendaring is obtained

- Remove wrinkles and creases

- Smooth fabric surface can be obtained

- Very high glossy fabric is achieved

- No risk of displacing of fabric

2. Chassing Calender

- It is similar with swizzing calender

- 5-7 rolls are needed & all of them rotate with same speed

- The major difference is “ the cloth makes several passage through the nips before it exits to a take-up roll

- The cloth is compressed as 5-6 layers being superimposed and entering into the nip again

- At this the weft of one layer will lie in between two adjacent wefts of the next layer and give additional pressure

- Roller pressure and this additional pressure soften the fabric and gives a linen appearance (soft feel)

Advantage

- Gives very smooth linen appearance

- Produce soft handle

- More the fabric is passed, more the glazy appearance is achieved

- Removes wrinkles and creases

3. Friction Calender

- Friction calender apply friction force to the face of the fabric

- Friction is done by driving the pattern roll faster (5-10%) than the support bowl

- Here, strong fabric is needed to withstand the strain

- Friction produces a high degree of lustre at one side and gets similar effect to ironing with hot air

- It is generally 3 bowl m/c

- Middle bowl is made with polished iron, heated and speed is more than its bottom roller

- Pressure between bottom two bowls are more depending on the amount of starch and moisture in the fabric, the starch deposited on the fabric varies

- If MC> 20%, starch sticks to bowl and if it is <15%, no lustre is produced

- Generally a friction calender runs at 31.5 m/min

- Highly lustrous, glossy surface, heavy closing up of threads, iron effect can be achieved

- It is mainly used for share, lungi, bed sheet etc

4. Compaction calender

A compaction calender has an adjustable gap between the pattern roll and the bowl. The nip point between the two rollers is set as per design requirements to regulate fabric thickness. It enables the production of filter media with a controlled and consistent thickness.

5. Embossing calender

A specialized type of calendaring machine, usually built with 2–3 bowls. The middle bowl is engraved with the desired design, while the other bowls are softer (often cotton bowls) to press the pattern effectively. The metallic engraved roll is smaller in diameter (about 20 cm) compared to the soft compressed roll (about 60 cm). The smaller roll produces sharper and deeper embossing effects. Fabric is pressed and deformed according to the engraved design, and both rolls may be heated to improve the effect. Commonly used for thermoplastic fibers.

6. Schreiner calendar

This process gives cotton fabric a silk-like brilliance. It is commonly applied to sateen, cotton linings, and printed fabrics. A finely engraved steel or linen roller is used, typically with 250–350 lines per inch. The lustrous effect depends on the fabric construction and the direction of the engraved lines. Engraving can have either a V-shaped cross-section, which produces a higher sheen, or a U-shaped cross-section, which results in a softer luster. The engraved lines may appear sharp or rounded.

10 Facts on Calendering in the Textile Industry

- Provides highly lustrous appearance on the fabric surface.

- Provides smooth, glossy and silky touch to the fabric.

- Increases fabric cover factor

- Compress fabric and reduce thickness

- Causes a closing to-gather of the threads by flattening them & thus tending to fill up the inter stiches between warp and weft.

- Reduce air permeability by changing its porosity

- Increase opacity of fabric

- Reduce yarn slippage

- Flattens slubs

- Consolidation of non-woven

How calendering is carried out?

When wet process is carried out on fabrics, the fabric loses its luster and remains at creased form. To compensate this problem, calendering is carried out.

3 main elements of calendering

- Heavy pressure

- High temperature

- A suitable degree of dampness

Damping can be achieved in 3 ways:

- Brush damping

- Spray damping

- Damping by steam

Calendering machine construction

- Calendering machine consists of two or more massive rollers which are compressed by means of hydraulic or pneumatic pressure and have high temperature.

- The most important factor in calendar design is the composition of the rollers and the surface characteristics of these rollers.

- One roller is considered as the pattern roller and is responsible for finished appearance of the fabric.

- While the other roller is called ‘bowl’ and serve to transport the fabric through the m/c. Number of bowls 2-7.

- Normally no of bowls 3, 5, 7 with the most common being the three-bowl calendar. Number of bowls are more for heavy or jute fabrics.

- Two types of bowls are used:

1. Metallic (1/2 inch metal wire on bowl)

2. Compressed material (1/2 inch rubber or synthetic leather on bowl)

- Metallic and compressed bowl should be placed by one after another, otherwise fabric should be cut.

- However, a lot of modern calendars are made with thermoplastic thick covering which is usually Nylon 6. These are less liable to damage from knots, seams and creases.

- Nylon 6 covered rollers often enable the required effects to be achieved in a single nip thus reducing the overall number of bowls.

- The metallic bowl should be rotated with positive motion by the gear to prevent slippage, but the compressed materials bowl should be rotated with surface contact.

To Wrap up!

Different types of Calendering process plays an important role in textile finishing. Without these, fabrics are unable to sell in the market as if it is not done, the fabric will lose its appeal.