Fabric Shrinkage Test (Dimensional Stability) in Garments & Textile Industry

The Fabrics Shrinkage Test is performed to find out the dimensional stability after washing. It is also known as the Dimensional Stability of Fabric. This testing is done after the fabrics finish and before cutting for garment manufacturing. To determine Fabric Shrinkage to adjust Patterns as per Buyer’s Spec and assure Buyer’s Measurement is maintained in the bulk production by Fabric Shrinkage test. I present the Fabric Shrinkage Test (Dimensional Stability) in the Garments & Textile Industry.

These tests also help in fabric selection, setting washing instructions, and ensuring conformity on the production floor. The report outlines the relevance of fabric shrinkage testing, some of the main methods for testing, and the impact on industry-wide garment quality control.

Dimensional Stability/ Fabrics Shrinkage Testing Method

- Fabric shrinkage test is not applicable for non-washable woven garments. This is not limited to any other special fabric that may require a specific % for the shrinkage test.

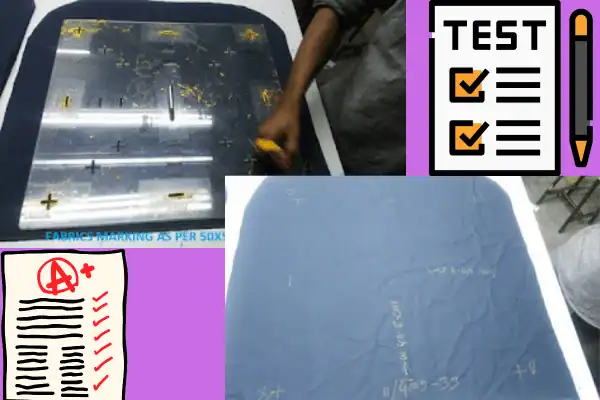

- Fabric Q.C shall select for knit fabrics, spandex fabric 100%, and woven 10%. This is not limited to any other special fabric which may require a specific % for shrinkage test of the total number of rolls and cut 50cm x 50 cm in each roll selected. Some factories cut 25cm x 25cm fabrics swatch to find out the dimensional stability after washing.

- Shall mark a square of exact 50cm x 50cm and Roll No, Lot name, L & W for Length and Width of the fabric by using a marker with un-washable ink.

- Shall wash these swatches as per the Buyer’s approved wash standard and dry.

- Need to ensure by the quality department that these swatches have achieved the correct standard for a wash effect, hand-feel, and shade as approved by the Buyer.

- If the standard is achieved, shall iron these swathes and re-measure each swatch, and make records to determine the Length and width-wise shrinkage.

- Then the fabric QC shall record the actual shrinkage of the swatches representing the roll numbers and submit it to the QC manager and Patternmaker to finalize the Average shrinkage to determine how many patterns are set to be utilized and to prepare.

- Finally, this completed “Fabric Shade Width wise segregation” and “Shrinkage Report” to be signed by QM, Pattern Master, stores in-charge, and copies to be distributed to Store, Sample Room, and Cutting in-charge. (The cutting in charge shall utilize this report for the preparation of the Cut plan and Fabric request.)

Fabric shrinkage testing is another major aspect considered in the textile and garment industry to ensure dimensional stability and maintain product quality. This first step gives the manufacturer an idea of how fabrics behave under washing, drying, and other treatments in order to prevent post-production defects and better customer satisfaction. The standardized methods- AATCC, ISO, and ASTM- provide very reliable data that assist in material selection and care labeling.

In summary, rigorous shrinkage testing strengthens a brand’s ability to produce durable, well-fitting garments, thereby minimizing returns and complaints. As consumer demand grows for quality and sustainability, so will the need for ongoing advancement in shrinkage testing methods continue to be essential for the successful position of the textile industry.

- You may love to read: Fabric Testing Machines List in the Textile Industry.

- Fabric Testing Standards and Methods